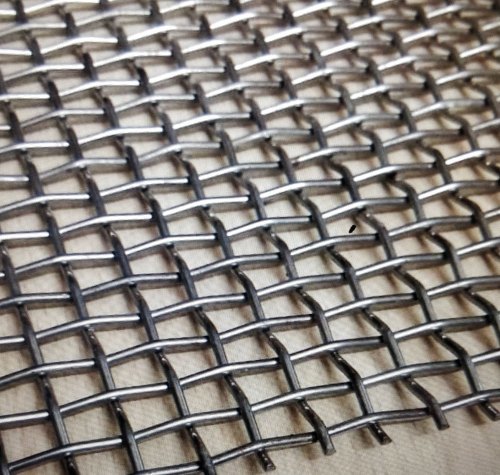

Crimped Wire Mesh Manufacturers

Crimped wire mesh is a versatile and long-lasting material that is utilized in a wide range of industries. It has better filtration, air flow, and toughness. Crimped wire mesh may be tailored to individual needs by varying mesh sizes, wire diameters, and aperture patterns.

It is used in mining, construction, filtration, and other fields, offering a reliable and affordable option for a wide range of requirements. It is also well-known for its resistance to corrosion, ease of setting up, and little upkeep. It is used in tasks ranging from architecture to industrial filtration and delivers safety, aesthetic appeal, and dependable performance. As a result, this article will give you useful knowledge on crimped wire mesh.

Real-World Applications of Crimped Wire Mesh

Because of its versatility and good qualities, crimped wire mesh is widely used in a variety of sectors. Here are a few examples of real-world applications using crimped wire mesh:

- Mining and Quarrying: Crimped wire mesh is extensively used in the mining and quarrying industries for filtering and sorting various sizes of aggregates, minerals, and ores. It provides effective classification and boosts extraction output.

- Construction and Architecture: Crimped wire mesh is used in architectural projects for ornamental reasons, façade cladding, and interior design components. It provides aesthetic value to structures while also providing ventilation and shade.

- Industrial Filtration: Crimped wire mesh is used in industrial filtration systems for solid-liquid segregation, air filtration, and dusty confinement. It successfully eliminates contaminants and assures clean air or solutions in a variety of sectors, notably pharmaceuticals, food processing, and the treatment of wastewater.

- Animal Enclosures and Cages: Crimped wire mesh is utilised in the building of wildlife enclosures, cages, and aviaries. It provides a safe and long-lasting boundary for housing animals in zoos, farms, and research institutions, assuring their well-being and control.

- Petrochemical and Refining: Crimped wire mesh is used in petrochemical and refinement operations to support catalysts, filter corrosive liquids, and separate various chemical compounds. It can tolerate scorching temperatures and hard situations and yet work well.

- Automobile and Transportation: Crimped wire mesh is used in automobile operations such as radiator grilles, speaker covers and headlight protection mesh. It delivers strength, ventilation, and shielding while remaining sleek and attractive.

You may also like to read - Wire Mesh Manufacturers

Advantages of Crimped Wire Mesh

Crimped wire mesh offers several advantages that make it a preferred choice in various applications. Here are some key advantages of using crimped wire mesh:

- Durability and Strength: Crimped wire mesh is constructed using high-quality materials, such as stainless steel or galvanized steel, which provide excellent durability and strength.

- Versatility: Crimped wire mesh is available in a wide range of configurations, including different mesh sizes, wire diameters, and opening patterns. This versatility allows it to be customized to specific requirements, making it suitable for diverse applications in different industries.

- Enhanced Filtration and Separation: The crimped structure of the wire mesh creates a strong interlocking pattern, ensuring efficient filtration and separation of particles, liquids, or gases. It provides precise control over the size of the openings, allowing for accurate filtering of desired materials.

- Good Ventilation and Airflow: Crimped wire mesh offers excellent ventilation and airflow properties. Its open design allows for the passage of air, making it ideal for applications that require proper ventilation, such as HVAC systems, industrial drying processes, and agricultural settings.

- Aesthetic Appeal: Crimped wire mesh can be designed with various patterns and finishes, adding an aesthetic appeal to architectural and decorative applications. It can be used to create visually appealing facades, partitions, and interior design elements.

You should also know about these stainless steel wire mesh suppliers

Crimped Wire Mesh Weight Chart

Crimped wire mesh weight varies according on its dimension and wire diameter. Here's a weight chart for crimped wire mesh:

Mesh Size (in inches) | Wire Diameter (in inches) | Weight (lbs/sq.ft)

Considerations for Choosing Crimped Wire Mesh

Certain aspects must be considered while selecting crimped wire mesh for your individual application to ensure best performance and appropriateness. Here are some crucial points to remember:

- Material Selection: Crimped wire mesh is possible to be made from a variety of materials, comprising stainless steel, galvanised steel, and other alloys. When selecting a material, consider surroundings, chemical exposure, and needed strength.

- Mesh Size and Wire Diameter: The mesh size relates to the number of holes per linear inch, whilst the wire diameter defines the thickness of the wire employed. Choose the mesh size and wire diameter based on the filtration or separation needs of your application.

- Opening Shape and Pattern: Crimped wire mesh aperture might be either rectangular, square, or hexagonal. The opening design can be interwoven in a variety of ways, comprising plain weave, twill weave, and Dutch weave. When selecting the opening form and pattern, keep the individual application requirements and intended functionality in mind.

- Strength and load-bearing capacity: Examine the load-bearing specs for your application. Ascertain that the crimped wire mesh chosen has the requisite strength to bear the predicted loads and pressures having no deformity or rupture.

- Corrosion Resistance: If your application includes exposure to moisture, chemicals, or corrosive factors, use crimped wire mesh with corrosion-resistant qualities. For corrosion resistance, stainless steel or galvanized steel are frequently selected.

Also read about the brass wire mesh here

Finally, crimped wire mesh is a versatile and important material utilised in a variety of industries. Crimped wire mesh has many benefits, and with a large range of sizes, materials, and patterns available, it can be adapted to individual requirements in applications.

Crimped wire mesh offers reliable durability and inexpensive alternatives in mining, construction, and industrial filtration. Measures for the same should be made while selecting the appropriate crimped wire mesh. You can maximise the potential of crimped wire mesh for your individual needs by recognising its benefits and making educated selections.