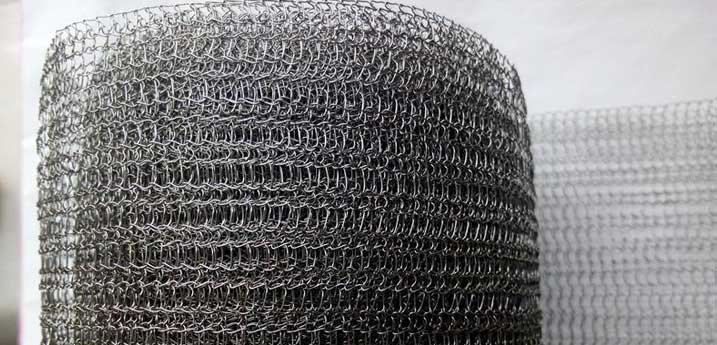

Knitted Wire Mesh Manufacturers

Numerous modern cycles require the utilization of Knitted wire Mesh. Filtration, sound stifling, warm protection and EMI/RFI safeguarding are only a couple of the applications they are utilized in.

Knitted Metal Tech offers exceptional necessities of every application.

- The Knitted wire mesh presented is additionally profoundly adjustable.

- We can make wire Mesh in different shapes, aspects, and materials to meet the necessities of our clients.

- Its flexibility permits it to serve various areas.

- A group of experienced specialists can work with clients to foster custom wire mesh that meet their careful determinations. This guarantees that buyers get the very Mesh they need to arrive at their objectives.

Knitted Wire mesh features

- A Knitted wire mesh is an adaptable texture with numerous purposes like filtration, detachment, protecting and protection.

- Contingent upon the expected use, knitted wire mesh determinations might differ, yet the accompanying general necessities ought to be thought of.

- Knitted wire cross sections can be produced using various materials including tempered steel, copper, aluminium, and nickel.

- The decision of material relies upon the expected use, climate, toughness required, and so forth.

- The wire distance across the Knitted texture additionally changes relying upon the application.

- A meagre wire is adaptable and comparable, while a thick wire has major areas of strength for is strong.

- Mesh size depicts the quantity of wire mesh lines per inch. More modest lattice sizes give better filtration or partition capacity, while bigger cross-section sizes permit more air or fluid stream.

- The Knitted width of the wired mesh changes relying on the use conditions. More extensive widths can be utilized for bigger undertakings, while smaller widths are frequently utilized for more modest applications.

You should also know about these wire mesh manufacturers in India

Why Pick Manufacturers for Knitted Wire Mesh?

- We have top-notch fabricating offices here.

- Our certified workers use cutting-edge hardware and better-quality unrefined substances than make industry-accommodating mesh.

- As one of the main players on the lookout, we can offer excellent Mesh at the best costs. In case of a lack of unrefined components on the lookout, having natural substance metals in stock permits us to satisfy orders cost-really.

- With an emphasis on quality, flexibility and client care, the organization is strategically situated to keep addressing the requirements of different enterprises.

Determinants of knitted wire manufactured

- We work in manufacturing wire mesh plates and circles from 8 lattices to 150 cross sections in different metals like tempered steel, electrified iron, metal, and copper.

- We make circles from 4" to 10" and have all metals in stock for quick conveyance. We can likewise make plates as per client prerequisites.

Also consider reading about wire mesh screen manufacturers in India .

Advantages of knitted wire mesh

Knitted wire mesh is a flexible material with several advantages, such as:

- High Strength: Knitted wire mesh has outstanding strength and durability since it is produced from premium stainless steel wire mesh . It can survive challenging conditions, sweltering heat, and hefty loads.

- Flexibility: Because wire mesh is knitted, it is flexible, making it suited for use in applications like seals and gaskets that call for movement or flexibility.

- High Surface Area: The wire mesh's knitted construction offers a high surface area, which is advantageous for applications requiring a sizable surface area for filtration, absorption, or diffusion.

- corrosion and oxidation resistant , which makes it perfect for use in severe locations or applications where exposure to moisture or chemicals is a problem.

- Heat Resistance: Knitted wire mesh is an excellent material for use in high-temperature applications such as heat exchangers or exhaust systems since it can endure high temperatures without melting or deteriorating.

You may also like to read - Wire Mesh Filters Suppliers

What qualities portray a solid Knitted wire mesh manufacturer?

Consider these fundamental elements while looking for a solid Knitted wire mesh maker:

- Results of Superior grade: A respectable weaved wire mesh maker ought to give products of the greatest type, meeting or surpassing industry prerequisites. They ought to just use the best parts and work with learned experts that are devoted to making things of the best type.

- Customisation: To fulfil their clients' specific prerequisites, a respectable Knitted wire mesh maker needs to give a wide decision of customisation options. To make and deliver a specific wire mesh Mesh that fulfils every client's specific requirement, they ought to have the option to team up intimately with them.

- Client care: An extraordinary weaved wire mesh maker ought to be client engaged and offer first-class help. They should answer rapidly and really to any challenges that emerge from client enquiries.